Products

Basic Ramming Mass / Mixes

INDUCTORAM 'X' INDUCTORAM 'XC' INDUCTORAM 'XA' INDUCTORAM 'XC85'

This is a magnesite based ramming mix for medium / high frequency induction furnace, melting various types of ferrous / non-ferrous metals. Processing of the raw material is done with modern machineries to avoid any sort of contamination. Tailor made material is manufactured keeping in view the size of the crucible and type of the metal.

INDUCTOTOP

Magnesite based ramming mass for making the top & spout of induction furnace, with special bonds to form a strong chemical bond with Sodium Silicate.

Method to use: Material is to be mixed homogeneous with 4-5% diluted Sodium Silicate & water. Then after it is properly applied on the top and spout.

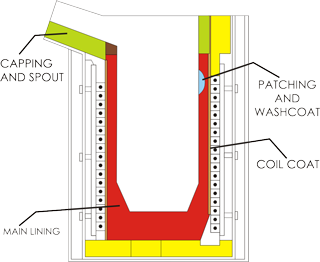

INDUCTOPATCH

Material is to be used for the patching of worn out parts of the crucible. Cracks in the lining can also be filled with the same.

Method to use: Material is to be mixed with 5-6% 1:1 solution of Foundry Grade Sodium Silicate and water. Homogeneous mixing is required to be done. Area to be patched should be neatly dressed off slag, for better performance.

INDUCTOCOAT

Material is to be used for giving coating to water cooled copper coil.

Method to use: Homogeneous mixing is required to be done with 6-8% of plain water in order to get material in the form of paste. It is to be applied on coil. Drying can be done by putting 500 / 1000 watt bulbs insite the crucible.

| Specifications | Inducto Ram | Inducto | Inducto | Inducto | |||

|---|---|---|---|---|---|---|---|

| 'X' | 'XC' | 'XC85' | 'XA' | top | patch | coat | |

| MgO% | 88 | 70 | 85 | 70 | 70 | 70 | 88 |

| Cr2O3% | - | 8 | 8 | - | 8 | 8 | - |

| Al2O3% | - | - | - | 20 | - | - | - |

| SiO2% | 8max | 8max | 5max | 8max | 8max | 8max | 8max |

| Grading [ mm ] | Ceramic | Ceramic | Ceramic | Ceramic | Chemical | Chemical | Chemical |

| Sintering Temp oC Min. : | 800 | 800 | 800 | 800 | 800 | 800 | - |

| Application Temp oC Max. : | 1750 | 1750 | 1750 | 1750 | 1750 | 1750 | - |