Products

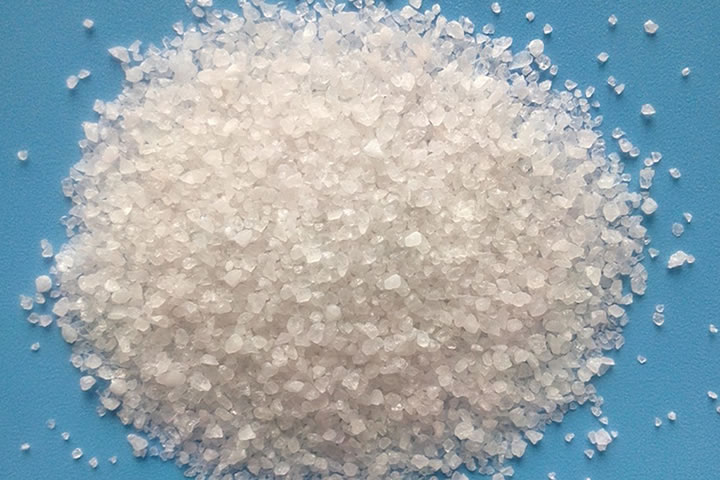

Foundry Sands

Mineral rocks obtained from mines are crushed, washed, dried and beneficiated to form sands.

Different types of sands are used for making the core and mould in foundries. In this particular foundry application apart from the chemical composition of the mineral, grain size distribution is very important. Thus after the cruising and beneficiation process is over presize sizing of the grains is done making the grain size distribution suitable for the application. There are various types of sands with different and distinctive properties like:

- "High" thermal conductivity

- "Low" thermal expansion

- High fusion point

- Good chilling properties

- Good refractoriness, etc..

Chromite

| Specifications | Chromite |

|---|---|

| Cr2O3% | 45 |

| MgO% | 10 |

| SiO2% | < 1 |

| Al2O3% | 12max |

| Size (AFS) | 45 - 55 |

Applications

- Temperature-Loadable mounding sand in foundry

- Used to harden steel, to manufacture stainless steel and to form alloys

- Efficient and Cheaper Substitute of Zircon Sand especially for high quality manganese steel Casting

Olivine

| Specifications | Olivine |

|---|---|

| Cr2O3% | 45 |

| MgO% | 10 |

| SiO2% | < 1 |

| Al2O3% | 12max |

| Size (AFS) | 45 - 55 |

Applications

- Blast cleaning

- Iron ore processing

- Lasers

- Open hearth stoves

- Foundry sand

- Abrasives

- Tundishes

- Forsterite bricks.

- Refractories

- Aggregates

- Ladle linings

- Soaking pit bottoms

- Welding electrodes

- Roofing tiles

- Electric arc furnace

- Hot tops